New feature release! Live webinar 2/19 @ 11am PST Register now

Table of contents

Table of contents

Even a small mistake could lead to a serious accident on a construction site. On-the-job training construction programs help install a strong safety culture among workers, making your work site a secure, more appealing place to work.

According to the Association of General Contractors, 68% of construction firms say that applicants lack the skills they need to do the job. In an industry like construction, where the risk is high and the margin for error is low, on-the-job training is essential. In this article, we’ll explore core construction training topics, health and safety fundamentals, and how to make your job site a safer place to work.

Essential on-the-job construction training topics

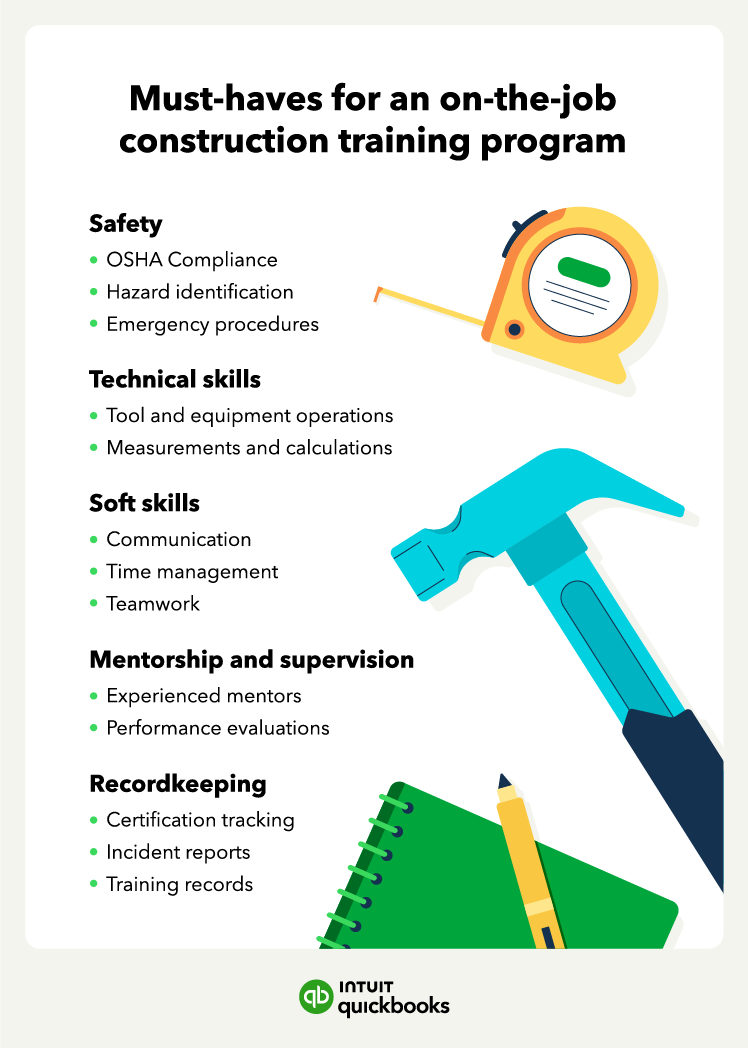

On-the-job training construction programs improve the success and safety of your building efforts. These programs equip workers with the skills and knowledge they need to perform their roles safely and effectively.

On-the-job training in construction helps your team master the skills necessary to keep them safe and productive. When you prioritize hands-on training, you’ll help build a more competent and confident workforce.

Health and safety fundamentals

The Occupational Safety and Health Administration (OSHA) training program is a cornerstone of construction safety training. OSHA-certified training helps your workers become aware of safety protocols and understand how to avoid common hazards on the job site.

OSHA construction safety training usually includes topics like fall protection, hazard communication, and personal protective equipment (PPE). The goal is for workers to become better equipped to identify potential hazards and take the necessary precautions to protect themselves and their coworkers.

Without an OSHA certification, employers may face stiff penalties for non-compliance. Employers who receive citations for serious violations can be fined up to $7,000 for each violation.

First Aid and CPR

Construction workers need to know how to respond in an emergency, including knowledge of first aid and how to administer CPR. First aid and CPR training can mean the difference between a minor injury and a serious one. In some cases, even life and death. You can find first aid and CPR training courses by visiting the American Heart Association and Red Cross websites.

Construction math and measurement

You have to be precise when making measurements and calculations in construction. Mastering these skills helps workers learn how to read blueprints, accurately measure materials, and make the right calculations when cutting, aligning, and installing parts.

As a result, construction projects will be completed to specification, and materials used as intended. Some courses include:

- Copeland Technologies: Construction Math

- 102 Essential Construction Math

- Reality Works: Measurement Math

Electrical safety basics

Does your team come into contact with electrical systems or equipment? If so, they need to know how to interact safely with them. Electrical safety training includes topics like how to identify electrical hazards, how to use tools and equipment safely, and understanding the proper procedures for working with live circuits. This training helps prevent severe injuries and even death.

According to the Electrical Safety Foundation, 6% of all workplace fatalities were caused by contact with electricity.

Some training courses include:

- eSafety’s Electrical Safety Training

- OSHA Academy’s Electrical Safety for Technicians and Supervisors

Material handling and rigging

Construction workers interact with all types of materials and need to know how to handle them properly. These trainings teach workers how to safely lift and move head loads using massive equipment like cranes and forklifts.

Rigging and slinging training are especially important because they also involve using objects like ropes, slings, and chains to secure loads for lifting. By using these machines and their components safely, you’ll reduce the risk of injury and death on the worksite.

Some training courses include:

Welding techniques

Welding requires a combination of technical knowledge and hands-on experience. On-the-job training in welding offers workers both by showing them how to weld safely and efficiently.

Whether working with steel, aluminum, or other materials, welding training involves understanding different types of welding and how to use welding equipment properly. By learning these skills, workers are better equipped to avoid burns, electric shocks, and exposure to harmful fumes.

Some training courses include:

- The American Society of Mechanical Engineers: Practical Welding Technology

- American Welding Society

- Anvil Welding Institution: Industrial Welding Training

Also, keep in mind that technical skills aren’t the only things construction worker training is needed for. To keep worksites safe, you should also require these on-the-job-training construction fundamentals:

- Clear communication and teamwork: Train workers to communicate effectively and work together. Effective communication can prevent misunderstandings and create a safer, more productive work environment.

- Proper recordkeeping and documentation: Employers should keep accurate records and documentation when tracking progress, keeping safety records, and ensuring compliance with regulations. When you train workers in the areas mentioned above, make sure that they complete the necessary paperwork correctly and on time.

How to implement on-the-job construction training

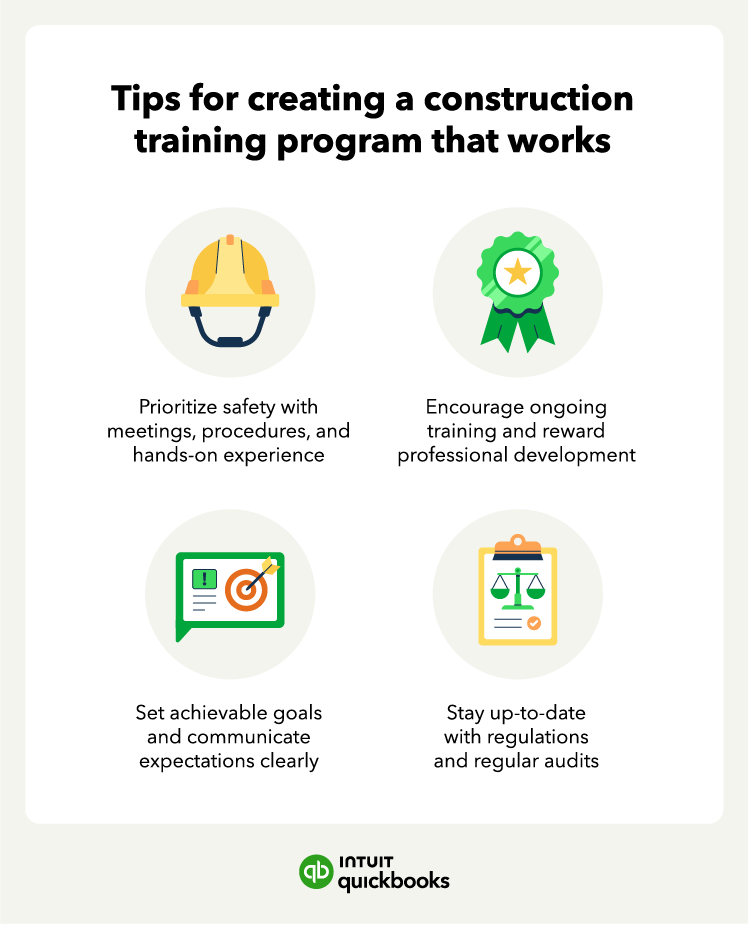

Creating an effective on-the-job training construction program requires diligent planning and execution. To help, here are a few steps to consider when implementing one:

1. Assess your training needs

What skills and knowledge do your workers need to develop or improve? Some areas can include safety, technical skills, or simply learning to operate equipment. Understanding these skills gaps will help you customize your training program to address the needs that matter most.

Use a skills gap analysis to identify specific areas where your workers need improvement. This can include surveys, interviews, or performance reviews.

2. Set clear training goals and objectives

What do you want to accomplish with your training program? Set specific, measurable goals that align with those of your company. Some of these goals may include reducing the number of on-site accidents or improving the quality of work performed. When you’re creating training goals, make them SMART: Specific, Measurable, Achievable, Relevant, and Time-Bound. By clearly defining your goals, you will better understand how to achieve them.

3. Develop a comprehensive plan

Now that your needs are acknowledged and your goals defined, it’s time to schedule training. Outline the topics you want to cover and the methods of instruction you will use, and create a timeline for completing the training. When drafting a plan, include time for learning how to perform tasks and hands-on experiences.

Cater to different learning styles by including various learning methods, like lectures, demonstrations, and hands-on practice.

4. Select qualified on-the-job trainers

The trainers you choose to work with your employees should be able to show their technical expertise and teach effectively. Look to the more experienced workers and supervisors on your job sites. Which of them can pass on their knowledge in a way that is easy to understand and replicate? Sometimes, training your workers properly requires the skill sets of more than one person.

5. Track progress and provide feedback

Track workers' progress through the training process and offer routine feedback to help them improve and stay motivated. Everyone teaches and learns a little differently, so adjust the training to ensure that everyone understands what they need to know.

6. Review and refine the training program

Here’s how to evaluate the effectiveness of your training program once the training is complete:

Ask yourself the following:

- What aspects of the training stifled workers?

- Where can you make improvements?

- Are your workers experiencing fewer on-the-job injuries?

- Are they more skilled and productive than they were before?

Analyze this information and refine your training program to make future improvements. It’s also a good idea to send out a survey to gather feedback from the workers who went through the training.

Updating your training programs to include new technologies and techniques helps you remain on the cutting edge of industry changes and ensures ongoing compliance with safety standards.

Real-world construction training examples

Not sure what types of on-the-job training programs you should consider implementing? Here are a few examples you can use as a starting point.

- OSHA’s 10-hour general industry training program provides a basic overview of key safety topics. These subjects include hazard communication, fall protection, and electrical safety. It’s an excellent foundation for any construction worker and should be a cornerstone in your hands-on training programs.

- Excavation and trenching safety: Excavation work can be very dangerous, from cave-ins to hazardous atmospheres. An excavation and trenching safety program can teach workers how to identify potential hazards and mitigate risk.

- Fall protection: More than one-third of construction deaths are due to falls, making them one of the leading causes of injuries and fatalities on construction sites. Fall protection training covers properly using harnesses, guardrails, and other safety equipment to prevent falls from heights.

- Hazard communication: Construction workers frequently interact with chemicals and other potentially harmful materials, so they should understand how to use them properly and the risks they pose. Hazard communication training teaches workers how to read labels, use Material Safety Data Sheets (MSDS), and follow proper safety protocols.

You can tailor all of these examples to meet the needs of your workforce while also remaining in compliance with OSHA construction training requirements.

Best practices of construction

Make the most of your construction training programs by adopting the following best practices:

- Supplement with classroom-style learning: On-the-job training is vital for any construction program, but combining it with classroom-style learning will enhance the overall learning experience. A hybrid training approach lets workers gain theoretical knowledge before applying it on the work site, making them more prepared for the situations at hand.

- Use diverse training methods: There’s no single right way to learn. Experiment with various training methods, like shadowing, mentorship, cohort-based learning, and discussion-based training, to address different learning styles and needs. Often, diversifying your training methods helps reinforce critical concepts and skills.

- Leverage technology for training: Use technology to make programs more interactive and accessible, further diversifying your training methods. For example, use mobile apps, online courses, and virtual reality simulations when possible. These tools offer hands-on experiences in a controlled environment, which can be helpful for more dangerous tasks.

- Get the whole team involved: Encourage everyone on your team, from entry-level employees to management, to participate in these training programs, creating a culture of continuous learning. Taking this approach helps reinforce the importance of safety and refines skill development.

- Provide ongoing feedback and coaching: If you want your workers to perform better and stay motivated, you should give them constructive criticism. Regular feedback helps employees understand where they can improve and how, and it recognizes their achievements when they do a job well.

- Measure training effectiveness: If you’re not tracking key metrics to assess how impactful your training programs are, you won’t know how well they’re working and where improvements should be made. For starters, track metrics like safety incidents, productivity, and job performance and use this data when reviewing and refining your training programs over time.

Confidently navigate challenges and opportunities in your construction business

On-the-job training construction programs are invaluable for midsized construction companies. Investing in comprehensive construction training programs can reduce the risk of accidents, boost productivity, and improve your chances of completing jobs on time and within budget.

Are you ready to implement a construction training program? Tools like QuickBooks’ construction accounting software can help you manage training, track progress, and stay compliant. If your construction business is more complex, consider Intuit Enterprise Suite, which helps you manage multiple entities and project-based accounting—all with tailored support. Start building a safer, more skilled workforce today!

On-the-job training construction FAQ

Disclaimer: This content is for information purposes only and information provided should not be considered legal, accounting or tax advice or a substitute for obtaining such advice specific to your business. Additional information and exceptions may apply. Applicable laws may vary by state or locality. No assurance is given that the information is comprehensive in its coverage or that it is suitable in dealing with a customer’s particular situation. Intuit Inc. does it have any responsibility for updating or revising any information presented herein. Accordingly, the information provided should not be relied upon as a substitute for independent research. Intuit Inc. cannot warrant that the material contained herein will continue to be accurate, nor that it is completely free of errors when published. Readers should verify statements before relying on them.

Customer stories

How FEFA Financial is growing with Intuit Enterprise Suite—without migrating to an ERP

How this mission-driven, employee-owned company created efficiencies with Intuit Enterprise Suite

Why this camping business chose Intuit Enterprise Suite over NetSuite

Migrating to Intuit Enterprise Suite took 2 hours (with zero disruption) for this aspiring $50M revenue business

Humble House Foods case study: How they improved visibility & simplicity using Intuit Enterprise Suite

More on construction

2025 Construction technology trends report: What are the opportunities of AI in construction?

ERP for construction: Managing costs & keeping building projects profitable

3 common mistakes preventing profitable growth in your construction business