New feature release! Live webinar 2/19 @ 11am PST Register now

Table of contents

Table of contents

Innovations like self-healing concrete, 5D Building Information Modeling (BIM), and automated robots are rapidly transforming the construction industry. For CFOs, these aren't just technical novelties; they're solutions to persistent challenges in cost management, safety, and profitability.

In fact, a recent survey found that 83% of bigger businesses are prioritizing these technologies specifically for the growth opportunities they unlock—and the challenges they address.

Let’s review the most exciting advancements in the industry today and explore their impact on current construction technology trends.

What's driving change in construction?

The construction industry is currently undergoing significant changes. Let’s explore some factors behind the most recent developments to help you understand the modern landscape.

Rapidly changing client expectations

Today’s construction clients are better informed and more aware of market changes than ever before. As a result, they increasingly demand custom structures that reflect the latest innovations in energy efficiency, security, and health.

In combination with a growing expectation for faster delivery times, this has accelerated a shift toward more modular, prefabricated construction methods. These are often faster and better suited to personalization and optimization.

Powerful capacities in technology

Thanks to ongoing advancements in technology, the tools available to construction teams are evolving rapidly. High-powered sensors, artificial intelligence (AI) software, and next-gen equipment are becoming increasingly affordable and accessible.

As more businesses incorporate these types of technologies into their operations, new capabilities and opportunities for efficiency are being unlocked.

For example, construction firms can now:

- Monitor job sites with drones to track project progress, materials usage, and safety practices in real time

- Use augmented reality (AR) to overlay plumbing or electrical blueprints onto the real world

- Automate construction tasks using robots that are much faster and more durable than human workers

Some bricklaying robots can lay as many as 1,000 bricks per hour. Meanwhile, the typical human mason lays around 300 to 500 bricks per day.

Burgeoning start-up environment

The construction industry has become a fertile ground for start-ups, as recent technological developments have created new opportunities for innovation and market disruption. Founders are rethinking legacy processes, putting pressure on established businesses to evolve.

For example, Mosaic built a platform that automates and optimizes the construction planning process. Despite using the same materials, workers, and procedures as traditional developers, Mosaic’s software allows it to build higher-quality homes faster and with less waste.

Emerging new-gen craftsmen

The next generation of construction professionals has arrived, and they’re bringing new ideas and attitudes to the industry. As digital natives, they’re more technologically savvy than their predecessors—more comfortable with electronic tablets and digital models than paper blueprints.

In addition to their openness to technology, these younger craftsmen tend to value flexibility and creativity in general. As a result, they’re often more willing to rethink processes across the board, pushing the industry forward in new and unpredictable ways.

Supportive legal frameworks

Governments and regulators are also contributing to the transformation of the construction industry. In particular, new CO2 mandates, energy efficiency regulations, and environmental incentive programs are pushing firms to adopt more sustainable practices.

As a result, companies are increasingly adopting automation and digital technologies that make their operations more eco-friendly. For example, AI-powered energy modeling tools are helping construction teams design buildings that use less energy and produce fewer emissions.

Innovations impacting the construction industry

Of the various factors driving change in construction, technological advancement may be the most significant. To help you understand its current landscape, let’s look at some of the primary innovations shaping the industry.

HD surveying and geolocation

High-definition (HD) surveying and geolocation are two of the most advanced modern mapping methodologies. Some of the most common techniques involved in these processes include:

- 3D laser scanning: This creates detailed 3D representations of objects and environments using lasers

- High-definition photography: Often done from drones, this creates photos detailed enough to show early signs of structural stress

- Geographic information systems (GIS): These can store, manage, analyze, and visualize spatial data from multiple sources

Construction teams can use HD surveying and geolocation to gain remarkable insight into the ground conditions at job sites. This improves their speed and accuracy and helps prevent project delays due to unforeseen terrain features.

5D Building Information Modeling (BIM)

Building Information Modeling (BIM) is the process of creating a comprehensive digital representation of a construction project, including its physical and functional aspects.

While traditional BIM systems operate in the usual three dimensions, 5D BIM adds two more: cost and time. This allows construction teams to visualize how design choices impact profitability and scheduling.

As a result, managers can use 5D BIM systems to inform their strategic decisions throughout each project’s lifecycle, preventing overspending while optimizing outcomes. Integrating 5D BIM with construction project accounting software is quickly becoming a critical best practice for real-time cost control and accurate financial forecasting.

In addition, some wearable AR devices now have 5D BIM capabilities. This allows on-site workers to overlay blueprints, project budgets, and timeline information onto ongoing projects.

Digital collaboration and mobility

Traditional construction firms have long struggled with fragmented and manual workflows. However, modern digital tools empower teams to communicate and collaborate much more efficiently.

These digital tools allow for seamless, real-time management of core functions, such as material cost tracking, crew scheduling, quality control, and safety compliance.

For example, cloud-based project management platforms allow teams to operate from a single source of truth, whether at the office or the job site. This significantly reduces errors due to version discrepancies and other miscommunication issues.

IoT and advanced analytics

Internet of Things (IoT) devices can capture and share data digitally. In the construction industry, this has created job sites where machinery, equipment, materials, and structures can all communicate with a central information platform.

With near-field communication (NFC) devices and embedded sensors, project managers can monitor mechanical and structural reliability, track inventory usage, and supervise productivity in real time.

In addition, advanced analytics tools can identify patterns in this data that managers can use to improve operations. For example, that might include optimizing and managing inventory levels, worker schedules, or maintenance timing.

Future-proof design and construction

The global building materials industry was valued at roughly $1.5 trillion in 2022 and is projected to grow at a compound annual growth rate of 4.1% through 2030. Its impressive size and continued expansion are partially due to the development of new and innovative building materials.

For example, some of these include:

- Aerogels: Solid but extremely lightweight materials derived from gels. They possess exceptionally low thermal conductivity, making them excellent insulators.

- Nanomaterials: These materials are between 1 and 100 nanometers thick, which gives them high mechanical strength, specific surface area, conductivity, and optical behavior.

- Self-healing concrete: This material contains chemical or bacterial additives that automatically fill cracks, extending the useful life of the structures they create and minimizing the need for maintenance.

In addition to helping developers complete construction projects faster, these materials can create more resilient structures, increasing safety outcomes while reducing long-term costs.

7 construction technology trends to watch

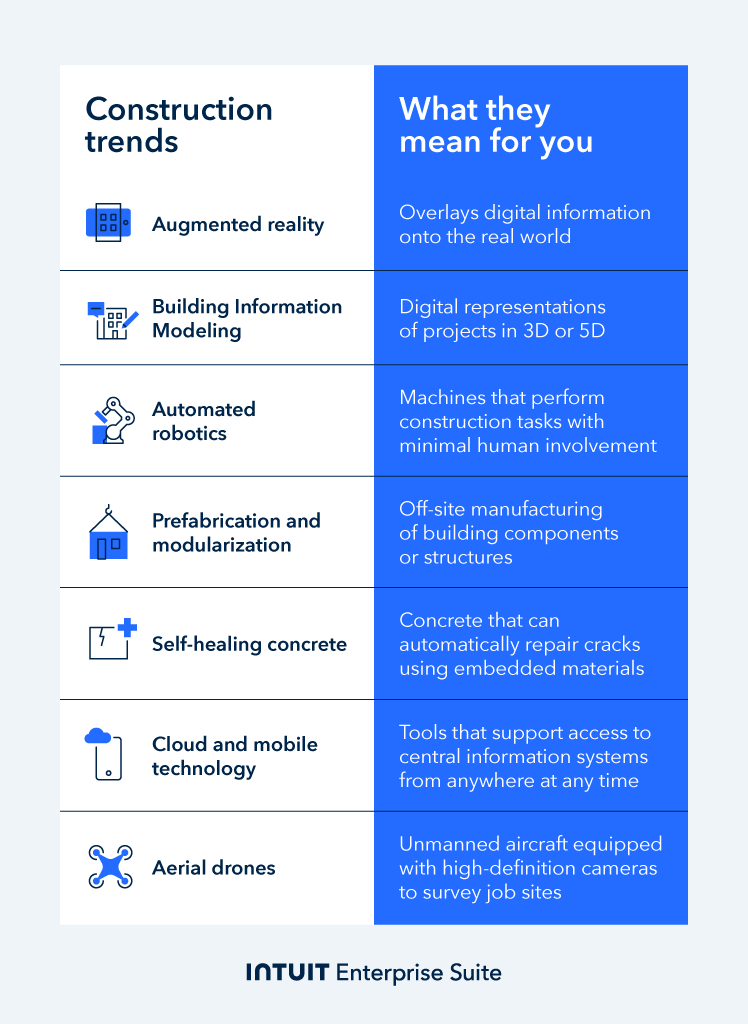

Previously, we covered some of the main innovations affecting modern construction. Next, let’s explore seven building construction technology trends you should be paying attention to. These will likely continue to shape the industry for years to come.

1. Augmented reality (AR)

While virtual reality (VR) technology immerses the user in a completely digital world, augmented reality (AR) devices superimpose a computer-generated image onto the user’s real-world view.

Both have their applications, but AR is proving to be even more useful based on construction industry trends. Most notably, users can overlay various types of valuable visual data over job sites.

For example, some of the common applications include:

- Detection of design and coordination errors in complex construction projects

- Displaying equipment components and other critical information, such as risk warnings (e.g., high temperature, electrical currents)

- Overlaying completed project plans on vacant sites for visualization, such as when discussing projects with clients

- Presenting BIM data through a visual platform for coordination on the job site

vGIS is a great example of AR in practice. This engineering-grade AR system, which integrates with BIM and GIS data, has been used on hundreds of capital improvement projects. Companies using this technology have reported an average return on investment (ROI) of 15:1, primarily by reducing errors, delays, and the need for rework.

2. Building information modelling (BIM)

BIM is one of the hottest construction technology trends in 2025. It’s transforming the building process by allowing teams to work off a shared digital model of a building’s physical and functional characteristics.

This allows teams to visualize developments in an open and highly collaborative environment, improving resource management, coordination, and communication throughout the project. According to recent research, 74% of contractors in the U.S. now use BIM, and its widespread adoption has been shown to reduce project planning time by up to 20% and material costs by 15%.

It’s especially effective in its 5D form, which incorporates cost and scheduling data. This gives teams a deeper understanding of project scopes, helping them increase productivity and shorten project cycles.

3. Robotics

What may have sounded like science fiction at the start of the century is quickly turning into a reality: robots are becoming an increasingly commanding force on construction worksites. They may not be able to handle the same dynamic and complex work that humans can, but they have several advantages over traditional workers.

These include better precision, speed, and durability for tasks like:

- Laying bricks and tying rebar

- Completing man-operated projects

- Lifting heavy objects and placing them in exact coordinates

Two types of robots are widespread: collaborative robots, designed to work safely close to human crews, and logistics robots, which transport materials and structures across worksites.

For example, the specialized construction robot SAM100 can lay approximately 3,000 bricks per day, which is a significant increase compared to the average of 500 bricks per day a human mason lays.

4. More prefabrication, modularization, and eco-friendliness

Multi-trade prefabrication involves building components from several trades off-site, such as plumbing, electrical, and HVAC. Similarly, modularization involves creating entire structures off site, from individual rooms to whole units or buildings.

These construction methods are becoming increasingly mainstream. They can help teams cut costs, streamline workflows, and improve outcomes compared to traditionally built projects. Standardization also helps reduce material waste, energy use, and lead times, making these approaches more environmentally friendly and attractive to progressive companies.

The Findlay apartment complex in Pittsburgh, Pennsylvania, is a good example of the benefits of prefab solutions. This large-scale residential development showcases how the method can be used to quickly address housing demand, with the off-site fabrication of 312 one-, two-, and three-bedroom modular apartment units, accelerating the entire construction process.

5. Self-healing concrete

Self-healing concrete is a material that can automatically repair itself as small cracks form, helping to prevent structural deterioration. Typically, it uses chemicals or embedded bacteria capsules that activate upon exposure to moisture, forming new limestone.

This can significantly reduce long-term maintenance costs and extend the lifespan of concrete structures, making it a potentially game-changing innovation for construction teams.

Self-healing concrete can be prohibitively expensive to manufacture, and adoption is still in its early stages. But the innovative material is expected to be increasingly incorporated into buildings, roads, and homes in 2025.

The cost to produce traditional concrete is typically between $65 and $80 per cubic meter, while the cost to repair it is around $147 per cubic meter. Self-healing concrete costs must dip below that threshold to become viable.

6. Cloud and mobile technology

Cloud operating systems and mobile devices have become the standard in many industries. They allow teams to access central information platforms from anywhere at any time.

The construction industry has embraced cloud and mobile technology. Firms are using it to facilitate collaboration between project managers and workers, whether they’re in the office or at the job site.

These platforms allow construction teams to store and share massive amounts of information digitally. That includes everything from project blueprints to materials usage reports and worker schedules.

With client expectations for quality, customization, and delivery times rising rapidly, this technology is becoming increasingly necessary for firms to meet their contractual obligations.

A 2023 survey found that 48% of construction firms are using cloud-based project management software, with a large number of these companies using it to improve collaboration and data sharing between the office and the field.

7. Drones

Construction teams started using drones around the early 2010s, and the industry has come to rely on them heavily in the years since. These tools quickly proved to be invaluable for developers, allowing them to:

- Survey large areas in minutes instead of weeks or months

- Prevent project disruptions due to unknown ground conditions

- Save time and money by streamlining the creation of more precise budgets and plans

- Monitor work sites from above to track progress, material usage, and safety compliance

For example, Brasfield & Gorrie began using drones with GIS data in 2022. They map and analyze job sites, then share the resulting insights with project teams to improve efficiency.

As useful as drones already are, the technology is still evolving rapidly, improving capabilities and unlocking new applications. In particular, integrating AI and machine learning promises to increase their autonomy and decision-making skills.

Boost productivity and enhance profitability

Recent innovations are creating new opportunities for disruption and driving current construction technology trends. Some of the most notable advancements include 5D BIM, self-healing concrete, and AI-operated machines.

AI can also help enhance your financial management, improving productivity and profitability. For example, Intuit Enterprise Suite leverages AI to help you automate key aspects of financial management, including finance, accounting, and project management.

When you schedule a demo, you agree to permit Intuit to use the information provided to contact you about Intuit Enterprise Suite and other related Intuit products and services. Your information will be processed as described in our Global Privacy Statement.

Customer stories

How FEFA Financial is growing with Intuit Enterprise Suite—without migrating to an ERP

How this mission-driven, employee-owned company created efficiencies with Intuit Enterprise Suite

Why this camping business chose Intuit Enterprise Suite over NetSuite

Migrating to Intuit Enterprise Suite took 2 hours (with zero disruption) for this aspiring $50M revenue business

Humble House Foods case study: How they improved visibility & simplicity using Intuit Enterprise Suite

More on construction

2025 Construction technology trends report: What are the opportunities of AI in construction?

ERP for construction: Managing costs & keeping building projects profitable

3 common mistakes preventing profitable growth in your construction business